1. The recyclability of paper straw

Problem:

TheAugust 2019 article on Macdonald in Grande Bretagne relating to his 100% bio-based but non-recyclable paper straw in conventional waste centres made headlines because of the thickness of the straw that had been increased to withstand longer in the drink. Indeed, many petitions, one of which reached more than 200,000 signatories, had been carried outin response to the change of the plastic straw to Macdonald's paper straw,the petition was intended to ask Macdonald to remove thepaper straws broke downintot too quickly indrinks and found another solution.

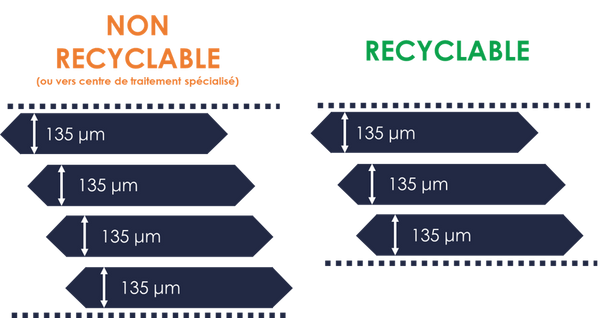

In response to this event, MacDonald responded by adapting its straws to make it more resistant, Macdonald added a layer of paper so that the straw usually composedof 3 layers has 4 of 135 micrometers thick. Certainly, the paper straw composed of 4 layers is much more resistant, 100% bio-soured but it is no longer recyclable, the waste centers are forced to burn it, which ultimately makes it even more polluting than plastic straw.

OSTONE solution:

OSTONE paper straws are made up of 3 layers of 135 micrometer thick paper that make them recyclable in conventional waste centres. OSTONE chooses notto offer strawscomposed of 4 layers to ensure optimal recyclability. Even though OSTONE paper straws contain only 3 layers of paper, they are more resistant than straws composed of 4 layers of traditional cellulose paper.

2. The strength of paper straw

Problem:

Unfortunately, the resistance of straw composed of conventional cellulose pulp is very low in resistance over time. The conventional paper straw can withstand an average of 6 minutes in water at room temperature (20oC) and about 1 minute in water at 100oC. The consumer experience is strongly affected.

OSTONE solution:

OSTONE's resistant fiber straw can withstand 2 hours in water at room temperature (20oC) and 1 hour in boiling water (100oC). OSTONE offers a straw made of patented paper. The strength of our straws is approved and certified by SGS.

Below is a test comparing conventional paper straws with OSTONE cellulose fiber straws:

3. Toxic inks from paper straws

Problem:

One of the problems of paper straws is customization with inks in order to give interestingpatternss and more attractive for branding a brand. This branding unfortunately has a heavy price, the inks used are in direct contact with the drink andthe body. This interaction has recently been revealedand toxic to the human body, the inks used in paper and cardboard packaging would be the cause of many cancerss and would even be more toxic than plastic. Thus, the paper straws will be toxic and not compliant withfood contact when printed with an ink, however it does not represent direct danger.

OSTONE solution:

That’s why OSTONE only distributes white straws and does not offer customization or printed patterns.

The composition of OSTONE paper straws (resistant fibers) is 99% FDA and FSC certified cellulose fiber and less than 1% FDA-certified paper glue.

4. Paper straws thatcontribute to deforestation

Problem:

To make 1000 kg of cellulose-based paper you have to cut about 18 trees (20,000 6 mm paper straws represent about 1 tree cut). The carbon footprintgenerated for the manufacture of this paper is 1,431 kg of CO2 and consumes approximately 2,770 litres of closed-circuit water. This impact on the environment is not negligible, most suppliers offer paper without justifying the sources of supply that often come from forests managed in an unsustainable way.

OSTONE solution:

OSTONE is committed to rigorously selecting its paper suppliers, including by selecting sustainably managed and certified FSC.

You can find the FSC certification of our OSTONE paper with the following code: A000523

5. Dangerous recycled paper straws

Problem:

Some paper straws come from recycled paper. Recycled paper is a mixture of papers already used, this mixture includes different categories of paper, for example, newsprint, printed magazines, packaging paper, books etc. Thus, recycled paper is mixed with substances that are not compliant for food contact and ink residues that can be toxic to the body.

OSTONE solution:

OSTONE offers resistant fiber straws by rigorously controlling theorigin of the paper and can ensure that it is food contact compliant, certified direct Food Contact FDA and it is 100% virgin origin. (Not recycled)

6. Paper straws that can alter the taste of the drink

Problem:

Classic paper straws alter the taste of the drink quickly in a cocktail. The drink will have a marked taste of pulp which is unpleasant and affects the quality of service.

OSTONE solution:

OSTONE has developed its super-resistant paper straw that minimizes this inconvenience. OSTONE resistant fibre straws are 100% bio-s bio-s and do not alter the taste of the drink (coldor hot content). This is due to the quality of the selected components.

Below on the left you can observe the OSTONE straw that resists and does not decompose in the drink, on the right a classic paper straw that breaks down and alters the taste of the drink.

7. Paper straws from China, unfair economy

Problem:

Classic paper straws are 90% produced in China, this production is often based on an unfair model. The situation of recent months in mainland China (coronavirus, plant shutdown) does not strengthen the reliability of the market. OSTONE visited many paper straw production plants in mainland China to conclude that the employees of these plants were sometimes in difficult working conditions.

OSTONE solution:

OSTONE has its production site in Asia but not in China. Our production lines are not impacted by the current situation in mainland China (coronavirus), our production is proceeding normally. In addition, OSTONE is moving towards a fair production model with modern infrastructure, and above-average compensation for employees.

8. Paper straws with plastic packaging

Problem:

The suppliers of paper straws offer for the most part an eco-friendly product (paper straw) but do not go through with it because they offer a plastic packaging. Plastic will be used for cost optimization (plastic is cheaper than paper).

OSTONE solution:

The packaging of our products is made up of biodegradable and recyclable cardboard boxes for the retail format (24 / 48 / 96). All OSTONE cartons are made of cellulose-based cardboard, our wholesale packaging is made of biodegradable and recyclable Kraft paper. The pallets we use are made of recycledwood. Plastic is not present at OSTONE.

9. Paper straws have a high carbon footprint for transport

Problem:

The transport of paper straws has an unmeasured carbon footprint, straw is a bulky product. The transport of paper straws includes a significant transport of air.

OSTONE solution:

OSTONE undertakes to disclose the carbone footprint associated with the transportation of itsgoods. Transportation is carried out by container by sea.

In parallel, we are developing a project to transport our goods by hybrid truck to minimize our carbon impact, the project will be deployed by the end of 2020.

10. Flexible and foldable paper straws

Problem:

Classic paper straws do not have the same character characteristics as foldable plastic straws. A foldable straw facilitates the consumer to drink his cocktail without orienting his head perpendicular to the straw. Flexible straws are also widely used in mass distribution for Condi-boxes and boxes tetra Pak.

OSTONE solution:

OSTONE offers its range of 180 paper straw, also called flexible paper straw, which takes up the latest technical challenge set between plastic straw and paper straw. This straw is composed of 9 rings that make it flexible, it is foldable at 180 degrees. The 180 range is only available with our resistant cellulose fiber.

Our 360 range is perfectly suited for retail and individual brick drinks e.g. Tetra Pak. This straw has a 360-degree flexibility. We recommend a diameter of 4 mm for this type of straw, available with our resistant cellulose fiber. We are ready to accompany you in large-scale projects.